- Gas Detector

- Gas Monitors

- Gas Analyzer

- Fixed Data Logger Scanner

- Clean Room Monitoring Equipment

- Internet Of Things (IoT)

- Temperature Humidity Transmitter

- Digital Stroboscope Tachometer

- Vibration Monitoring Equipments

- Gas Detection System

- Process Control Instruments

- Data Loggers

- Portable Gas Detectors

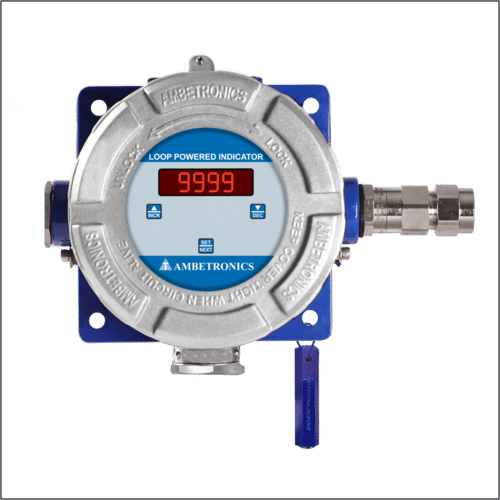

- Process Indicators

- Gas Alarm

- Calibration Kit

- Data Converters

- IIoT Loggers-Gateways

- Temperature Transmitter

- Sensors

- Gas Leak Detector

- Universal Data Logger

- Gas Leak Alert

Showroom

Clean Room Monitoring Equipments are acknowledged for their error free operation and RS-485 ModBus communication protocol supporting arrangement. These energy efficient systems have wide operating temperature range and these offer excellent analytical performance. Customers can avail these systems in wall mounted design.

Internet Of Things (IoT) Devices have important role in fast transferring of data by establishing connection between different systems via RS-485 /RS-232 serial port. These devices are reckoned for having 10/100 Mbps Modbus TCP speed, DHCP/Static IP Modes and energy efficient operation.

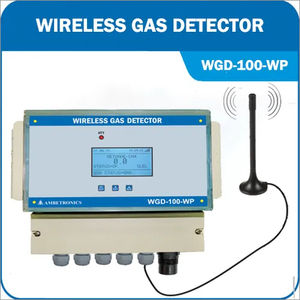

This range of micro processor controlled Gas Detection Systems is used for determining presence of harmful and flammable gases. These are equipped with advanced transmitter and dual channels for covering adequate area for detecting toxic gases. These are suitable for hazard prone working conditions.

Our huge collection of Process Control Instruments is acknowledged for its application of advanced technology, precise look, compatibility with laptop and computer. Simple to install, these instruments are appreciated for their precise look and robust construction. These systems are easy to maintain.

Offered Data Loggers are known for their long working life, accurate measurement technique and reasonable price. Designed by qualified personnel, these systems are appreciated for their ergonomic appearance. These are simple to control and maintain. We offer these systems at reasonable price.

Thermocouple and self-powered industrial sensors, among others, are produced and supplied by us. Fast temperature response is offered by thermocouples, which may be used in the majority of temperature measuring and control applications. We are ready to offer the top-notch sensing solutions.

Gas leak detector is widely known to detect flammable, combustible and toxic gases. This is apt for the locations, where emerging technologies are required. It is highly useful for firefighting applications.

Universal Data logger can adapt to several project requirements. It allows for the simultaneous monitoring of assorted analog and digital signal types. It is a simple to use and highly compact device.

Gas Leak Alert is widely used to detect the leakage of gas and prevents the possible disaster. It will keep you safe in several life threatening environments. It is an alert device of modish features.

|

AMBETRONICS ENGINEERS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |